As can be seen, several additional performance and visual enhancements were added to the software. In order to demonstrate that the object was truly being tracked, a bounding box was created. In addition, in order to increase performance, an added option to remove visual feedback was also added.

V. Conclusion

We believe that this project was most insightful for all team members. We learned a lot and faced various challenges. Not only was this design unique in the sense that a system comparable to this (4 motors in each corner) has never been implemented in an automated goalie before. But it also represented an opportunity for all of us to get out of our comfort zone and try to design something not found in an instructables page online. As we look back and reflect on the past semester, here are some lessons we took from our experience.

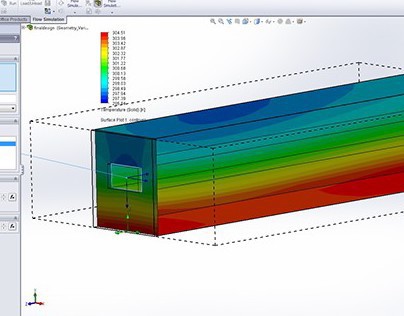

First, we now agree we had our priorities misplaced when it came to our design requirements. We wanted our goalie to have good precision in order to effectively block the ball which made us focus on steppers and servo motors. However, we later realized that given the size of the ball and the goalie, precision should not have been the main priority. In all our designs we were facing technical challenges related to speed performance and not precision. That should have been a signal for us to venture into brushless DC motors, which although are more complex to control and do not offer the level of precision that servos and stepper would, they are usually much faster. Therefore, the lesson learned here is to more carefully identify performance objectives in the early stages of the project (e.g. should we go for precision or speed).

The other lesson we learned was that diversity in a team is important in the work environment. Our team was composed of 5 product design engineers and one bioengineer. Although the team was good at breaking down and assigning work, It is possible that having a controls engineer on board might have kept us from spending time and money on testing out different means to make the equipment work as well as to provide better insight into DC control. However, although our team members had no hands-on experience with motors, motor control, or LabVIEW before this course, we also strongly feel that the lack of technical diversity was actually a positive thing in the context of a university course project. The roadblocks compelled us all to unite forces which developed our communication and teamwork skills and pushed us to learn new things. If our team was made of members each specialized in their own field, each member would be working on something he/she already knew and that would not have given us the opportunity to learn and explore new fields. In fact, we have all gathered more knowledge now about motors, LabVIEW programming, and computer vision which is extremely relevant for our career.

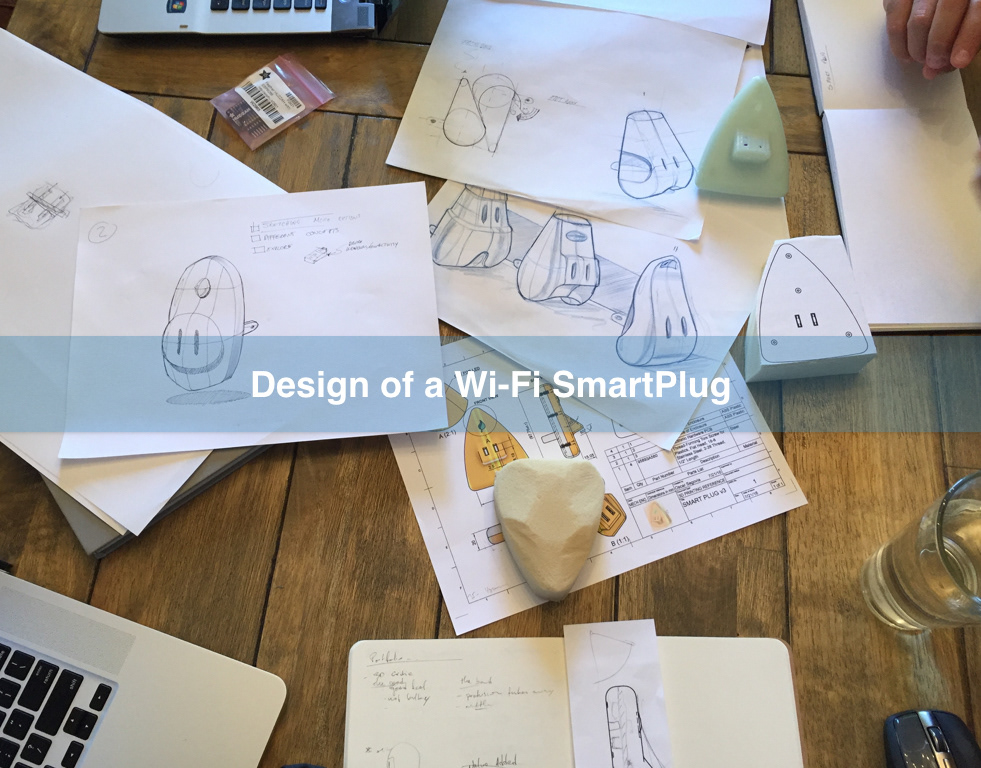

The third lesson we learned was that early stage prototyping is crucial. We went with a waterfall approach where we had consecutive milestones to reach. We thought that we should focus a lot on researching potential solutions, learning more about motors, calculating the power we might need, etc. to reach theoretically the best optimal product. We realized however that we learned best when we tried to prototype, failed, brainstormed solutions, and tried again. Therefore, we now feel that the best approach would have been to prototype a minimal viable product in the early stages to identify challenges that we would face early on in the process, overcome the challenges, and iterate until we reached the most optimal product. In short, the final spaceship that makes it to the moon shouldn’t be the first spaceship we build.

The final lesson we learned was that we should not have become “married to one design”. We focused most of our effort and time to try to make the 4 stepper motor design work. Yet, what we should have done was iterated more often, create subteams within the subteams to seek out lo-fi prototypes of distinct designs. Then we should have experimented with these various designs in the early stages instead of learning how to make one large design work. By following this method we would have evaluated each concept’s pros and cons, and followed through with the winning concept.

Overall, we believe this project was an amazing, challenging opportunity to grow as an engineer. Our team agrees that while having an time machine to go back in time would certainly change the way we approached the project, we appreciate the lessons learned in the incorrect approaches we did take. Would we change things if we had the opportunity to go back in time? Sure, but the strength of the lessons learned lie not in the past but rather in the future, where we now have the confidence and the know-how to tackle similar problems.

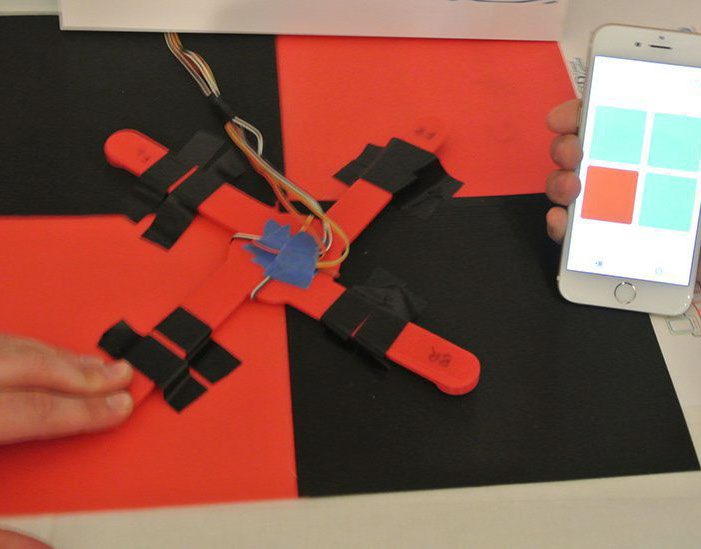

VI. User Test

A group of kids from OIS middle school attended our demo presentation. Although the project did not come out to our mechanical expectations, the kids seem to be intrigued by it and enjoy playing with it. They did not care that the ball was not being stopped all the time by the goalie. Kids did however, notice that the goalie would fail to follow the ball at times and would take advantage of this by kicking it faster and to areas where the goalie would not reach in time. They began kicking the small ball from afar, and got closer and closer to the E-goalie as time went on, making the system more error prone. At one point a kid grabbed the ball and began moving it in front of the camera, trying to figure out how the system worked. The kids, all had a great time. So much so that their teacher sent me a personal email thanking the group for our demonstration and to send us pictures and videos of proof that the kids had fun. Observations, demonstrate that integrating such a mechanical device with a sport like activity that kids recognize makes them more willing to participate. Although our initial intent of providing a skill improvement method is not necessarily explored in this user test, it does show the ability to attract a child’s attention while integrating a competitive component via the E-Goalie